The EPIC Low-Acid Solution Outpaces Demanding Market Trends

Supporting Your Product Portfolio Expansion

Current market trends reflect a consumer demand that is shifting away from just pure dairy to now include non-dairy, plant based, nut based, and caffeinated beverages. To meet these demands, manufacturers must conquer a considerable learning curve and changes in processing and establishing new critical risk-based control points.

Offsetting Additional Risks Associated with New Processes

Not only are processes changing to produce low-acid products, but these developments also introduce new risk points concerning product integrity and consumer safety. From a microbiological standpoint, this trend is complicating the ability of manufacturers to recognize their microbial challenges, understand their limitations, and uphold safety standards. Critical monitoring of diverse low-acid products requires precise handling of risk points for microbiological and chemical hazards including allergens. In addition, frequent change-overs of product and packaging increases the risk of microbial contamination.

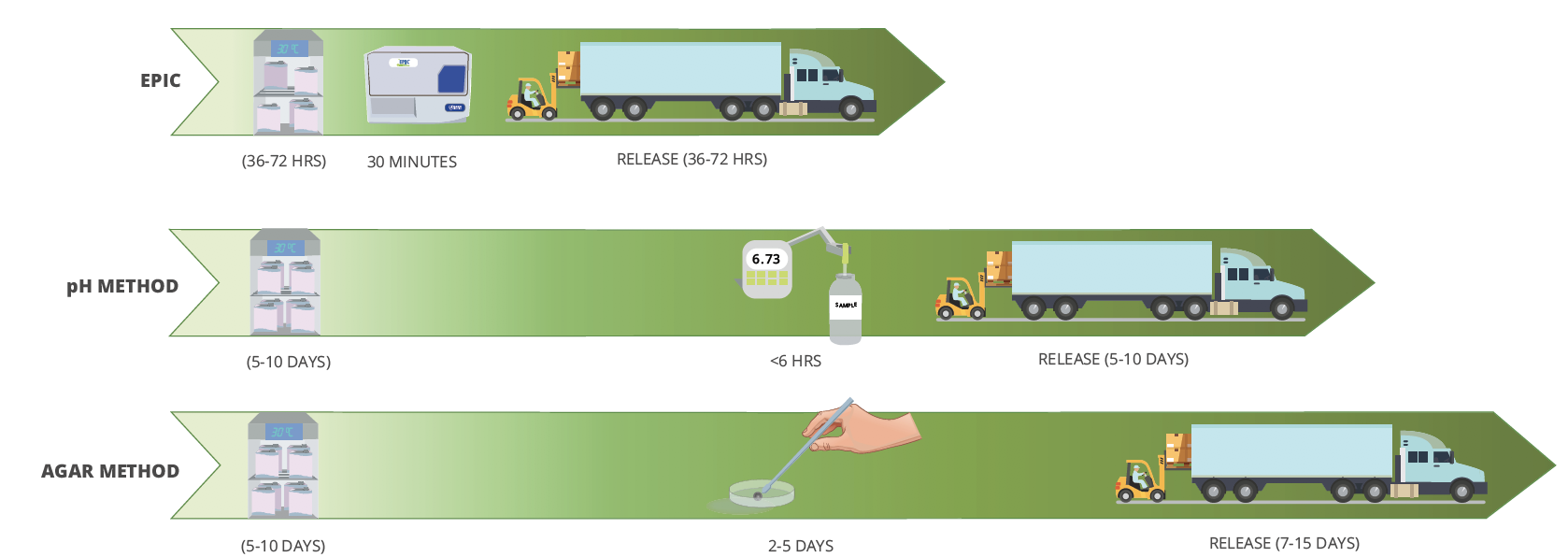

The Limitations of Conventional Microbiological Testing

Conventional microbial testing proves too slow to support modern just-in-time inventory management resulting in stalled delivery of these products to the marketplace. More critically, the time spent testing with traditional methods may not detect contamination events quickly enough to prevent costly product losses in extended production runs.

Most manufacturing facilities cannot afford the expense of keeping a microbiologist on staff. Without this skill level in place, there is significant room for error when performing and interpreting traditional microbial testing.

The Race Against Time

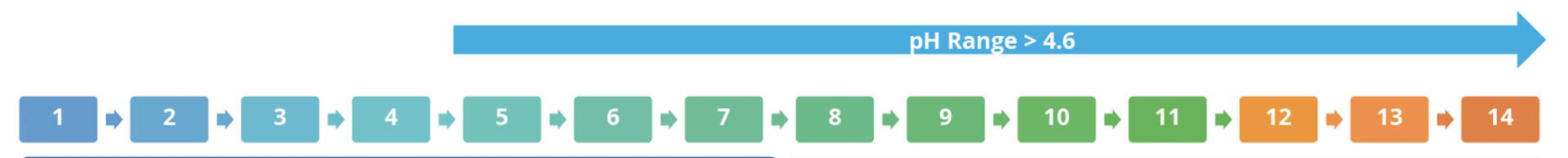

Utilizing a rapid microbial method results in a faster alert of a contamination event. In less than 48 hours you will be provided the invaluable opportunity to stop production and avoid greater losses.

Hold times will be significantly reduced for confirmatory testing allowing for faster evaluation, segregation, and release of quarantined product.

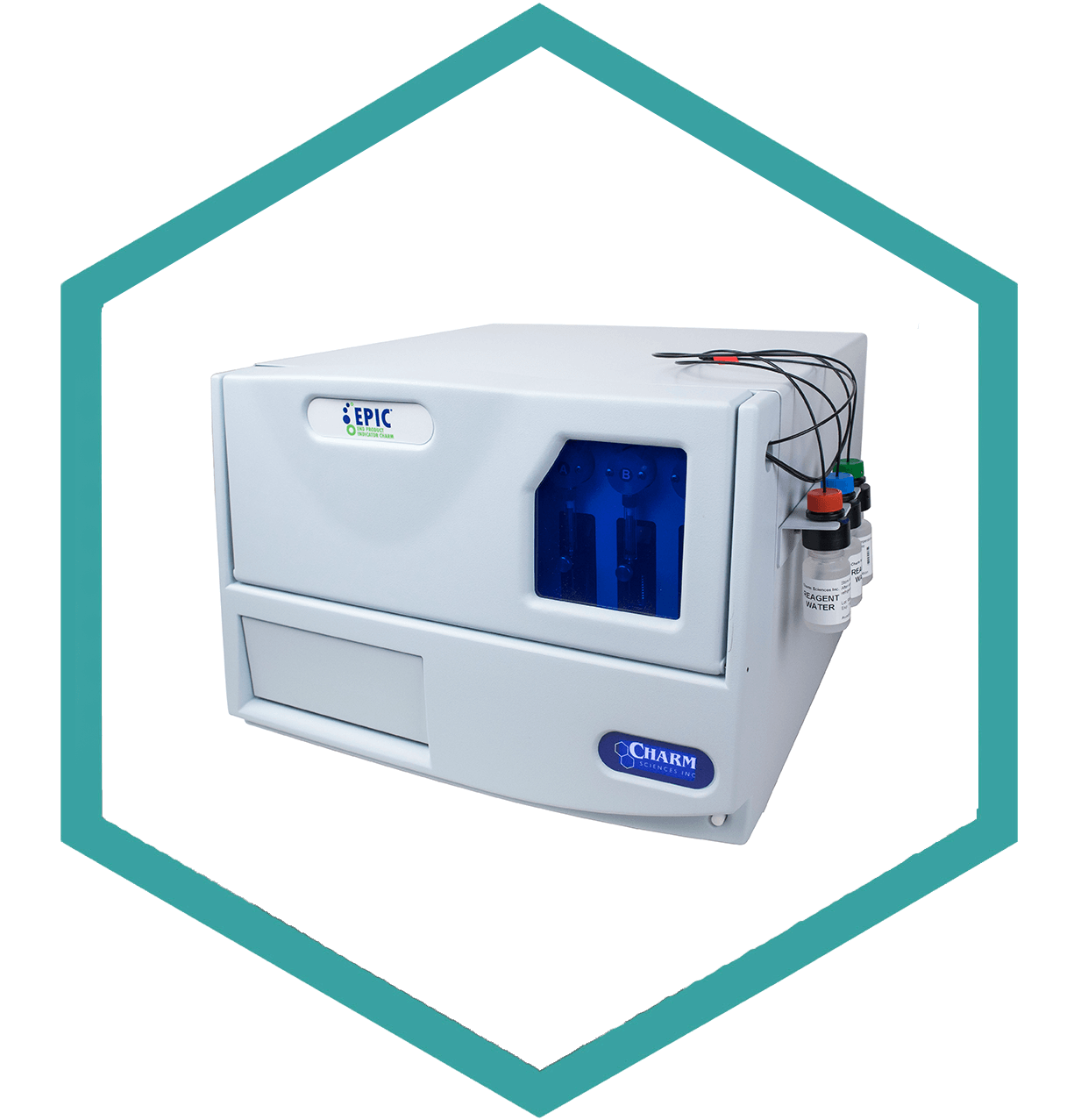

At Charm Sciences, we’re strategizing solutions that supplement this expertise, ensuring safe products are released to the market faster than conventional microbiological testing allows.

Expand Your Product Portfolio with Low-Acid Tests

Partner with Charm Sciences

By partnering with Charm Sciences, you will be able to streamline your laboratory’s testing procedures by using a single methodology that evaluates multiple product types. Using a single protocol, your laboratory can test a much wider range of low acid products, giving you an edge on your competitors when it comes to safety and speed.

Enhance Your Education with Strategic Support and Service

This new knowledge base needs support and that’s where Charm Sciences stands out from the competition. Our level of training and willingness to work in partnership with every single one of our customers will uniquely help you understand and manage the microbial challenges inherent in manufacturing a diverse range of low-acid products. Our depth of support is matched only by the breadth of our service.

Top Takeaways

Fast results reduce warehouse hold times

Only 24 to 48 hours incubation needed for most products

Less than thirty minutes of testing time for 96 samples

Multiple low acid products can be tested at once using the same single method

Supports low acid product diversification while keeping your CCPs under control

Partnership and 24-hour support

Contact Sales

Have a sales question? Send us a message and a sales representative will contact you.

By submitting your information via this form, you give Charm Sciences permission to contact you via email about updates, news, or offers that may interest you. It is Charm Sciences’ policy not to share any personally-identifying material obtained through our websites with any third party.